In modern manufacturing, custom metal stamping is a crucial process for achieving high-precision, high-efficiency, and high-volume production. Whether it's a simple metal bracket or a complex equipment housing, stamping technology can quickly and reliably meet the consistency and precision requirements of components across various industries.

Today, I'll introduce the key steps in custom stamping, common materials, applications, and how to choose the right metalworking partner.

What is custom stamping?

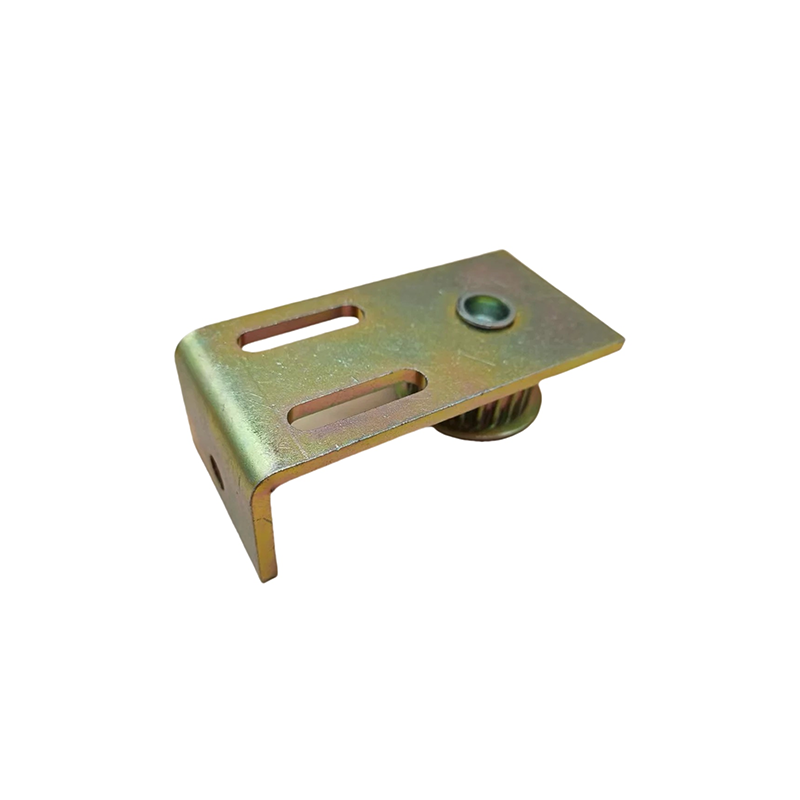

Custom stamping is a cold working process that uses dies and stamping equipment to create custom-shaped parts from sheet metal. During the process, metal (such as stainless steel, carbon steel, aluminum alloy, or galvanized steel) is fed into a stamping die and formed through a series of operations, including cutting, punching, bending, and stretching.

Common process steps include:

Blanking: Cutting the sheet metal into the initial shape

Punching: Drilling holes or notches at designated locations

Bending: Creating structural shapes

Drawing: Used for deep cavities, cup-shaped structures, and more

Embossing/Forming: Creating specific surface details or reinforcements

Common Materials and Surface Treatments for Stamping Parts

The performance of stamping parts is significantly affected by the material and post-processing. We support a wide range of industrial-grade metal materials, including:

Stainless steel (such as SS304 and SS316): Corrosion-resistant, aesthetically pleasing, suitable for outdoor or humid environments.

Cold-rolled carbon steel: Low cost, high strength, widely used in structural parts.

Aluminum alloy: Lightweight, with excellent thermal conductivity, suitable for the electrical and transportation industries.

Galvanized steel: With a built-in rust-proof coating, commonly used in construction and solar mounting systems.

We also offer surface treatment options such as powder coating, galvanizing, and electrophoretic coating (E-coating) to enhance product appearance and durability.

Advantages of Custom Stamping Parts

● High-precision, repeatable production

● Mold tolerance control ensures high product consistency across batches.

● High production efficiency and low unit cost

● Especially suitable for medium- to high-volume orders with fast delivery.

● Supports complex structural designs

● Enables intricate details such as bends, perforations, and ribs on metal.

● High material utilization and environmental conservation

● Automated layout reduces waste and saves costs.

Typical Applications of Stamping Parts

Elevator Manufacturing: Guide Rail Brackets, Magnetic Isolators, Connecting Plates

Construction and Municipal Engineering: Embedded Plate, Seismic Brackets, Metal Pipe Clamps

Automotive Parts: Mounting Clips, Reinforcement Plates, and Body Structural Parts

Equipment Housings and Electronics: Panels, Chassis, and Terminal Covers

Solar Energy Systems: Aluminum Alloy Mounting Brackets, Roof hook solar, Solar Panel Clip and Steel Foundation Brackets

Why Choose Xinzhe Metal as Your Partner?

As a company with many years of experience in metal product manufacturing, Xinzhe Metal Products provides one-stop custom stamping services to customers worldwide:

ISO 9001 quality management system certification

OEM/ODM services available, with quick response times for both sample and bulk orders

Strict quality inspection processes + complete export packaging and customs clearance documentation

Accepting a variety of payment methods (TT, PayPal, Western Union, etc.) and supporting global shipping

Contact us to customize your stamped parts!

Post time: Jul-31-2025