Angle steel is not just "L-shaped iron"

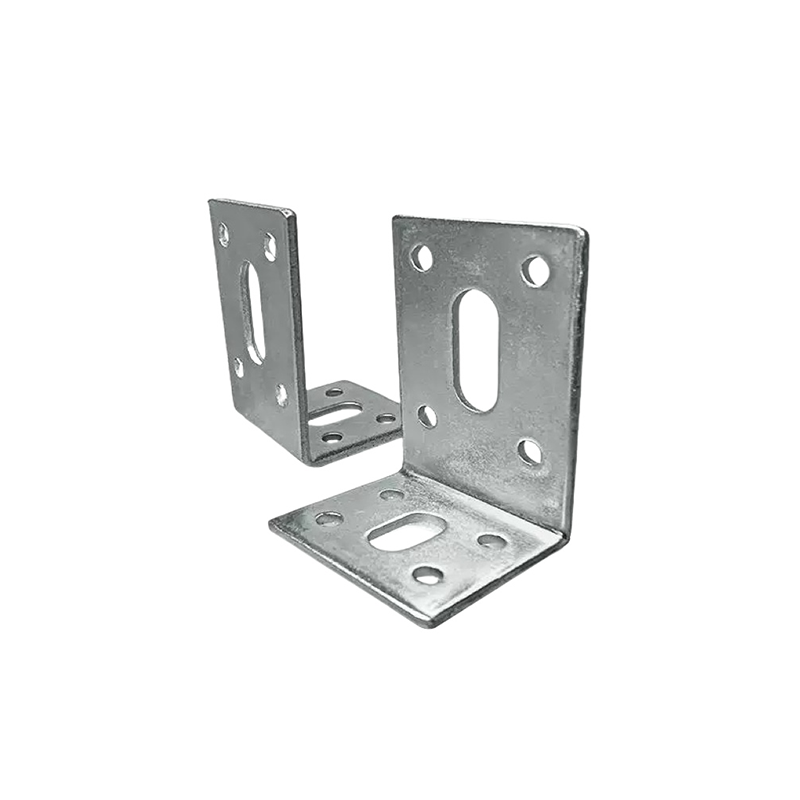

After being in the metal processing industry for a long time, you will find that many products that look "simple" are actually not simple at all. Angle steel (Angle Bracket) is one of the typical representatives. Especially the heavy angle bracket used for building support or equipment installation, it is not just a piece of bent iron, it carries the stability of the entire structure.

Recently, when we were in contact with customers, we found that many foreign customers would repeatedly ask two questions: "Is your angle steel heavy?" "Is the surface galvanized?" These two questions sound ordinary, but they actually reveal a common point: they are very concerned about the durability and environmental adaptability of angle steel.

The "heavy" of heavy angle steel is not weight but responsibility

The so-called "heavy angle bracket" does not actually refer to the simple "heavy", but the heavy task it has to undertake. For example:

● Fix the main beam in the steel structure factory

● Support the guide rail system in the elevator shaft

● Stabilize the column or panel in the solar bracket

These angle steels usually use steel with a thickness of more than 4mm to 10mm, and sometimes they are designed with reinforcing ribs, double rows of holes, notches, welding reinforcement and other structures to improve stability.

Why do people need to "galvanize"?

Galvanized steel angle brackets are actually a very smart process choice. The hot-dip galvanizing process can form a rust-proof zinc layer on the surface of the steel, greatly extending the service life, especially suitable for outdoor or humid environments.

We once supplied angle steel to a Middle Eastern customer. Their main concern was not the appearance, but "whether it can remain rust-free for 10 years in sandstorms and salt spray." Later, we specially gave them a thickened hot-dip galvanizing treatment, and the surface zinc layer thickness reached 85μm, which successfully passed the salt spray test.

"Small details" on the factory side that you may not know

Making angle steel seems to be bending, but there are actually many process control points:

● Is the bending angle accurate (if the error is large, the bolt hole will not be aligned)

● Is the hole position clean and burr-free

● Is the load-bearing surface flat enough

● Is the surface treatment uniform and bubble-free

We even encounter customers who require their own identification numbers on the angle steel for storage and classification, which involves customized services such as coding and packaging.

Therefore, angle steel is not as simple as "L-shaped iron sheet", especially heavy-duty galvanized angle steel bracket, which actually involves a whole set of manufacturing logic such as materials, structural design, anti-corrosion technology, processing accuracy, transportation packaging, etc.

If you are looking for a reliable metal angle steel supplier, you may wish to pay attention to the following questions:

1. Does it support customized size and hole type?

2. Can you provide anti-corrosion treatment such as hot-dip galvanizing and powder coating?

3. Can you place a small batch trial order?

4. Is there any actual load-bearing data or test report?

As a manufacturer specializing in sheet metal processing, we bend thousands of angle steels every day. Every L-shape is actually "stabilizing the foundation" for our customers' projects.

Welcome to leave a message or send us an inquiry drawing. We are happy to share the process details and are willing to discuss with you every seemingly simple but meaningful metal part.

Post time: Jul-18-2025